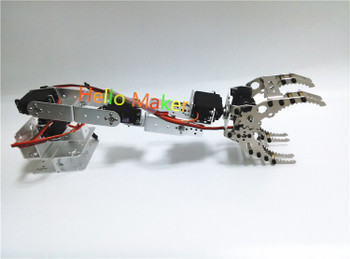

Description

Product Description

Technical Parameters

|

Payload

|

10 kg

|

||

|

Reach

|

1500 mm

|

||

|

Structure

|

Articulated

|

||

|

Number of axes

|

6

|

||

|

Repeatability

|

±0.05 mm

|

||

|

Max. motion range

|

Axis 1

|

±165°

|

|

|

Axis 2

|

+135°/-75°

|

||

|

Axis 3

|

+78°/-76.5°

|

||

|

Axis 4

|

±360°

|

||

|

Axis 5

|

±115°

|

||

|

Axis 6

|

±450°

|

||

|

Max. speed

|

Axis 1

|

148°/sec

|

|

|

Axis 2

|

148°/sec

|

||

|

Axis 3

|

150°/sec

|

||

|

Axis 4

|

222°/sec

|

||

|

Axis 5

|

222°/sec

|

||

|

Axis 6

|

360°/sec

|

||

|

Body Weight

|

≈120 kg

|

||

|

Mounting type

|

Ground, bracket, ceiling

|

||

|

Ambient temperature

|

-20 ℃~80 °C

|

||

Workspace

Main Applications

Materials handling, parts transfer, electric welding, machine management, palletizing, packaging, testing, deburring, grinding, gluing, assembly &painting

Applicable Cases

NC lathe loading &unloading The figure shows a NC lathe automatic loading &unloading solution provided for a customer. Combined with the production line, one robot can manage two face-to-face NC machines, thereby significantly reducing labor cost and time cost and enhancing productivity of the customer.

Detailed Images

Features of Robot Control System

High-precision technology, high load capacity, fast transmission speed, stable operation

Servo Motor

High-precision control, good high-speed performance and strong anti-overload capability

Servo Driver

Control the servo motor by three methods: position, speed and torque

Controller board

Including various interfaces such as IO module, safety module, A / V analog module

Aluminum Alloy Shell

Independent design, exquisite appearance, CNC machining and casting

Features of Robot Control System

●Structural optimization algorithm suitable for the body control of various types of structure.

●Modular setting of functions

suitable for diverse applications.

●8-axis control realizes the control of external axes (traveling axes and positioner).

●Suitable for multiple increments; absolute servo.

●Suitable for multiple increments; absolute servo.

●Open structure for synchronization of international technology and extension

of functions.

of functions.

●Software PLC functions facilitate logic control.

●Process functions make programming easy. ●Improved computer bus

connection ensures reliability and practicability.

connection ensures reliability and practicability.

●Safety module ensures safe production of the robots.

●Industrial standards &reliable stability.